Success stories

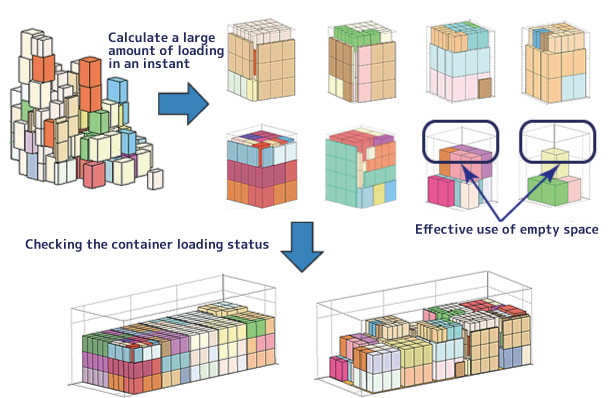

Loading Simulator is a software to calculate optimized loading solutions to save logistic costs.

Loading Simulator calculate best loading solutions with balance and efficiency for items of various shapes and sizes.

- ① Improve the bulk ratio for the pallet by calculating the loading

- ② Reconsider the loading process based on the results

- Pallet bulk ratio improved from 62% to 83%

- Reduced storage costs for distribution centers

- Reduced distribution center work costs

- Reduce transportation costs to distribution centers

Loading Simulator uses algorithm to calculate the best plan according to the shapes you load.

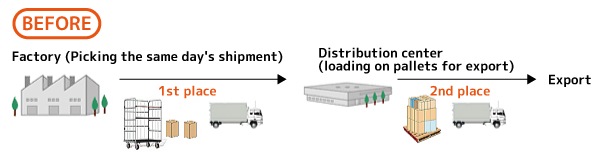

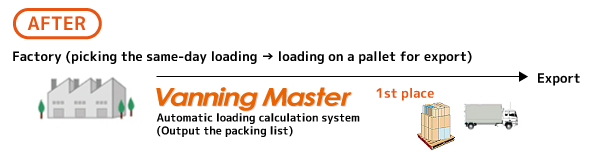

This company realized dramatic reduction of transportation fee by analyzing efficiency for very large amount of loading items.

In this case, the company also realized restructuring stowage location to one location.

* Calculation of 300 items ( quantity 17000 ) for each operation.

- Loading roll box pallets from the factory for shipment to distribution center

- Loading on pallets and making list at distribution center

PalletMaster realizes loading operation based on picking list which is automatically calculated with the software which makes loading operation considered export from when you pick at the factory.

PalletMaster calculate the best to prevent items from falling as well as efficiency.

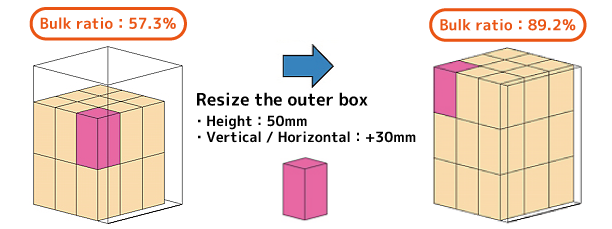

Loading Simulator is flexible for addition of the items and cancellation.

Also, it can adjust the sizes of boxes for simulation.

The more efficient loading planning is possible with calculation from the size of the boxes.

When there are too many items to load, sometimes efficiency was left behind.

With Loading Simulator, you can operate with efficiency and you can omit wasteful operation like sorting.

You can utilizes the space by precisely grasping bulk ratio and reducing pallets.

You can analyze the size of the boxes and loading efficiency.

You can adjust the size by testing with Loading Simulator.